注染工場に行ってきました Visited a Chusen Dyeing Factory

どうも杉前です。

インスタにも書きましたが昨年末に大阪堺にある株式会社ナカニさんまでオリジナルデザインの手拭い染色現場に見学と撮影に行ってきました。工場自体一年前に行き、今回で2度目。初めて連絡させていただいてから早一年。注染ならではのデザインにしたいなと試行錯誤している間に時間が過ぎてしまった。

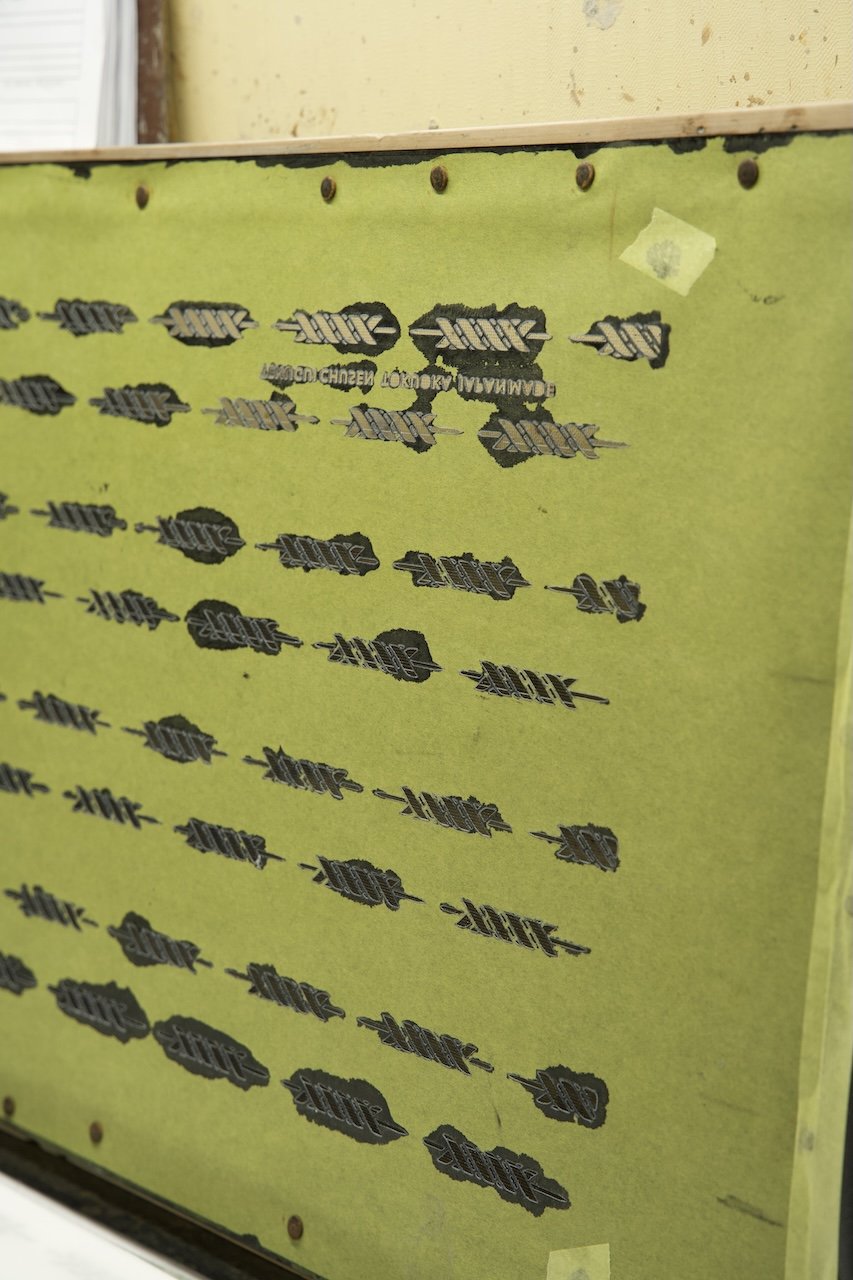

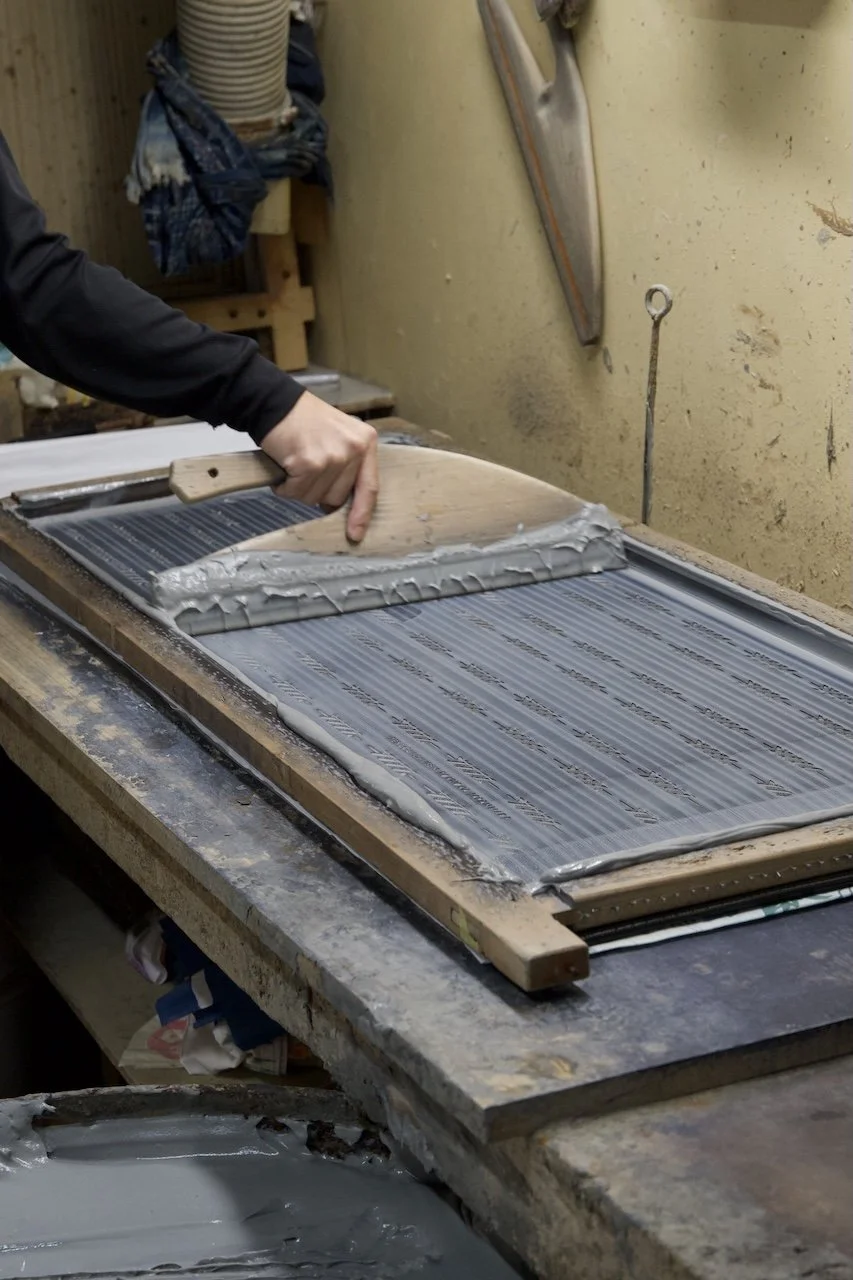

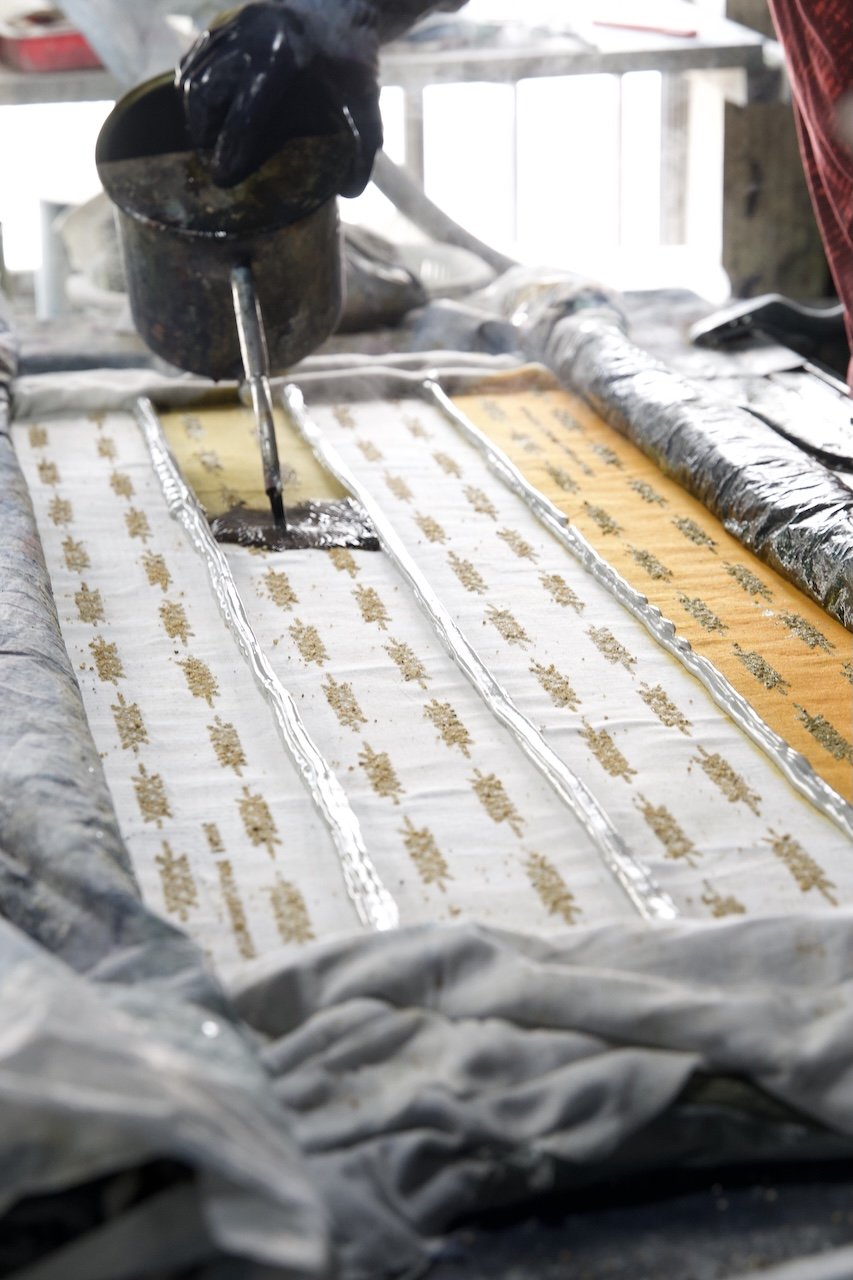

大阪発祥である注染は板締めからの派生で量産化のために開発された技法である。糊置きから乾燥まで一気に仕上げる職人の動きは一切の無駄がなく、糊の硬さ、色の調合、染料の流し加減など職人の感覚による工程も多いため機械化は難しく、束ねた晒し生地を染料が上から下に通過することで染まるため表裏がないのが特徴である。

一度に約50枚単位で製作するが一枚ずつ染料の入り方が微妙に違ってくる。デザイン仕様によってどうしてもブレが出るので現代の量産プロダクションの均一なものを大量に作る概念からは少しはみ出たものづくり、注染だけに。お湯を使うということもありそこら中に蒸気が立ち込めて布を通過した染料を吸い込むバキュームの音が合わさり産業革命の時代に飛び込んだかのような錯覚を起こす。

次回作の時にもぜひ現場を訪れたい。

As I mentioned on Instagram, at the end of last year, I visited Nakani Co., Ltd. in Sakai, Osaka, to observe and document the dyeing process for our original tenugui (hand towels). This was my second visit to the factory; my first visit was a year ago. It’s already been a year since I first reached out to them, and in the process of trial and error to create a design unique to the chusen dyeing technique, time has flown by.

Chusen, which originated in Osaka, is a dyeing technique derived from itajime (board-clamping dyeing) and developed for mass production. One defining feature of chusen is that dye penetrates bundles of cotton fabric from top to bottom, ensuring the design has no front or back side. The process involves skilled artisans performing seamless movements, from applying resist paste to drying, with no wasted effort. Many aspects, such as the paste consistency, color mixing, and dye flow, rely on the artisan's intuition, making the process difficult to mechanize.

Each batch typically produces around 50 pieces, but subtle variations in dye absorption mean that no two pieces are exactly alike. This natural inconsistency, which can vary depending on the design, gives chusen-dyed products their unique character. It’s a form of craftsmanship that steps away from the modern concept of creating perfectly uniform, mass-produced items.

The factory itself has a distinctive atmosphere. With steam rising from the use of hot water and the constant sound of vacuum machines extracting excess dye, it feels like stepping into a scene from the Industrial Revolution. This immersive environment was both fascinating and inspiring.

I hope to visit the factory again for my next project. Seeing the artisans’ work up close and experiencing the unique atmosphere of the workshop has been invaluable. I look forward to creating more designs that showcase the beauty of the chusen dyeing technique. Stay tuned!